Description

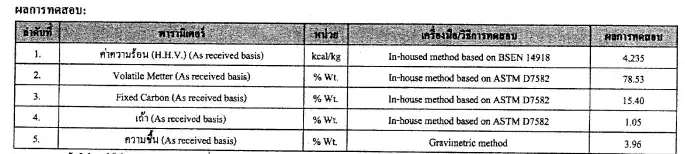

Test Results of Material Properties

| No. | Analysis Item | Unit | Testing Method/Instrument | Test Result |

|---|---|---|---|---|

| 1 | Higher Heating Value (H.H.V.) (As received basis) | kcal/kg | In-house method based on BSEN 14918 | 4,235 |

| 2 | Volatile Matter (As received basis) | % Wt. | In-house method based on ASTM D7582 | 78.53 |

| 3 | Fixed Carbon (As received basis) | % Wt. | In-house method based on ASTM D7582 | 15.40 |

| 4 | Ash Content (As received basis) | % Wt. | In-house method based on ASTM D7582 | 1.05 |

| 5 | Moisture Content (As received basis) | % Wt. | Gravimetric method | 3.96 |

Biomass Pellets / Compressed Sawdust

All biomass pellets are made from sawdust and dust generated during the company’s production process, without any contaminants or pollutants. The materials used are abundant and sustainable, ensuring eco-friendliness.

Biomass pellets are formed under high pressure, resulting in a uniform shape and texture, compact volume, and high density, making them easy to store and transport, thus reducing logistics costs. As a solid fuel, they are safe and stable for storage and have a long shelf life.

With high energy density, biomass pellets offer better combustion efficiency compared to traditional fuels, with a heating value comparable to medium-grade coal. The amount of carbon dioxide (CO₂) released during combustion is equivalent to the amount absorbed during the tree’s growth cycle, leading to a low carbon footprint, reduced pollution, and lower air contamination.

Biomass pellets are widely used in various combustion equipment, meeting the energy needs of households and industries, including heating and electricity generation.